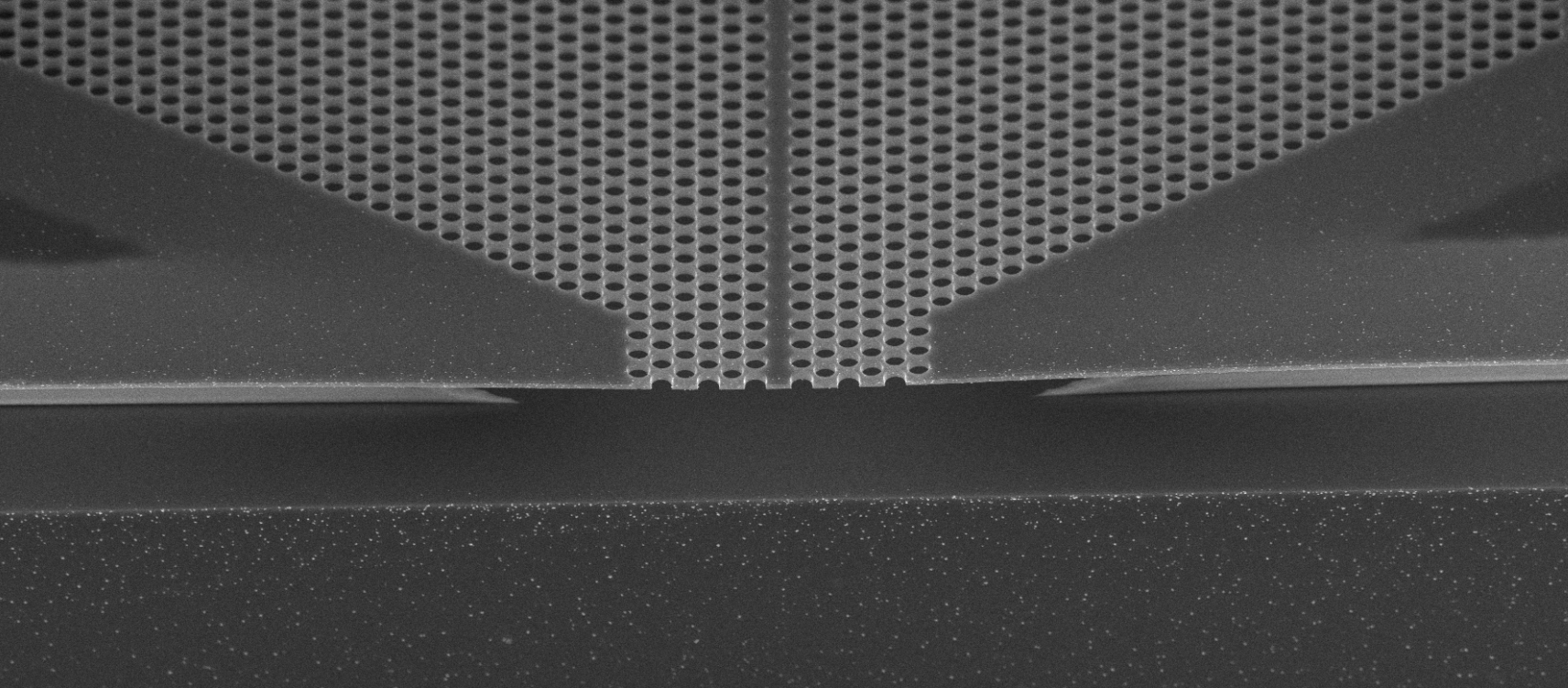

Sputter PVD system Polyteknik S-Flex

Sputter Physical Vapor Deposition (Sputter PVD) is a form of deposition in which a target material is bombarded with energetic ions under a relative low 10-2 mbar vacuum. The impact ion energy removes (sputter) material from the target. Normally argon is used as the sputter gas. The sputtered material is deposited on a substrate. The composition of the target material can change during this process. SiO2 as starting target material can loss some oxygen in the resulting deposited layer. With a heated substrate and introducing reactive gasses the resulting layer can obtain the desired properties. The system is build according our specifications by Polyteknik.

Specifications

- Polyteknik Flextura M506 S

- Sample size diameter 4” max 4mm thick

- Load lock

- Base pressure ~10-8 mbar (high vacuum; 400 l/s turbo, dry roughing pump)

- Ar sputter gas, reactive gas N2 and O2

- 4 Polyteknik 3” Magnetrons

- 300W RF power supply

- 2kW DC, uni or bipolar pulse mode power supply

- co-evaporation

- Quartz thickness monitor

- Sample heating till 500 °C

- Sample rotation

- Shutter system for sources and sample

- Automated recipe driven software