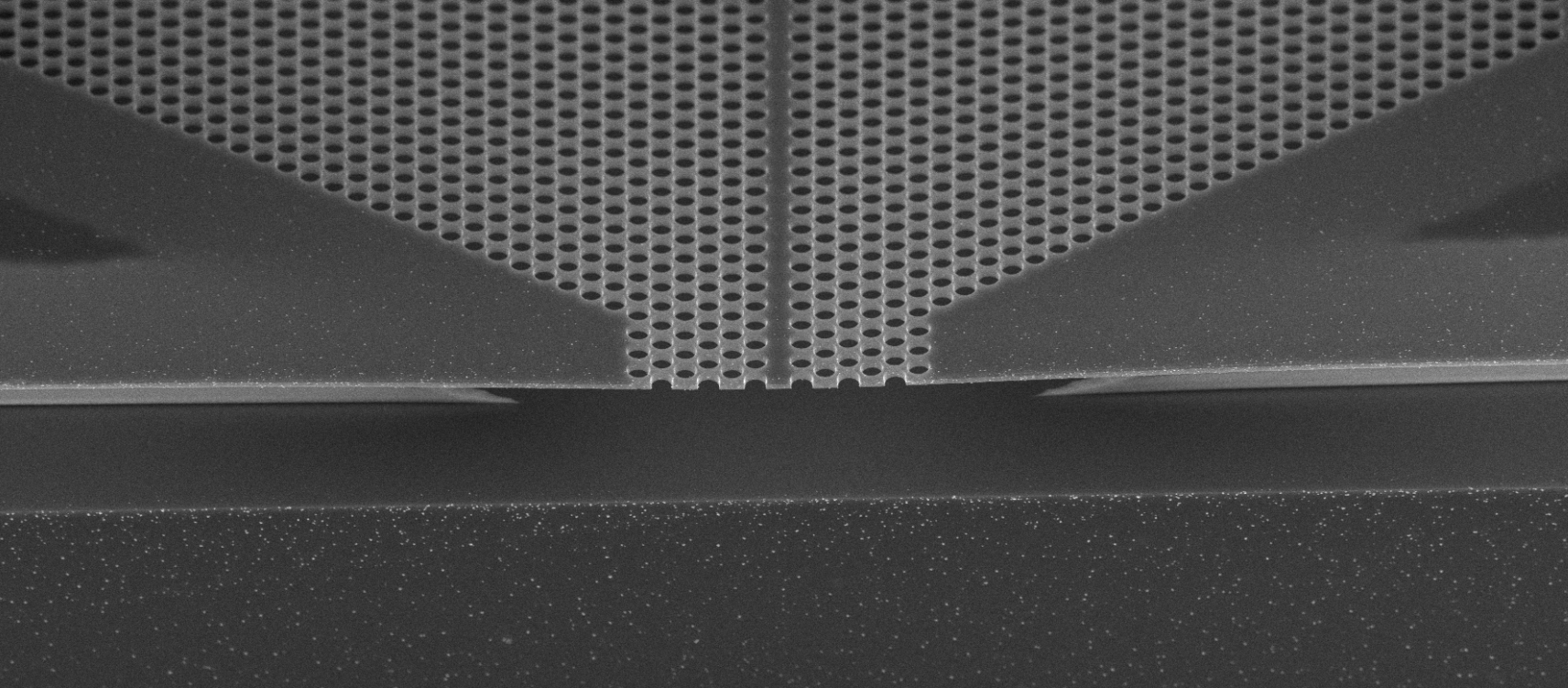

Raith e-LiNE lithography system

With an electron beam a pattern is written in a photoresist layer. After exposure to this beam it is possible to selectively remove either exposed or non-exposed regions of the resist with chemicals thus creating nanotechnology structures.

Specifications

- Sample loadlock

- Universal sample holder for small sample pieces up to 100mm 10mm max height

- Electron beam energy 10 – 50kV

- Beam current range 50 pA – 40 nA

- Beam size < 2.5 nm diameter at 50 kV

- Beam current stability <0.5% / h

- Beam position stability < 200 nm / 8h

- Patterning area 150mm by 150mm symmetrical

- Pattern generator 50 MHz pixel frequency

- 20 ns minimum dwell time

- Stage range x=150 by y=150mm z=20 mm

- Laser-interferometer X –Y stage with 1 nm position resolution

- Z – axis Laser Height sensing reproducibility 1 micron

- Write field stitching 35 nm in 500 micron write field

- Minimum feature size 20 nm in high resolution positive resist

- Mark recognition gives overlay accuracy of 35 nm

- GDSII format viewer and editor

- Import AutoCAD DXF,bitmap, ASCII or CIF format converted to GDSII

- Traxx and Periodixx software option

- FBMS and MBMS software option